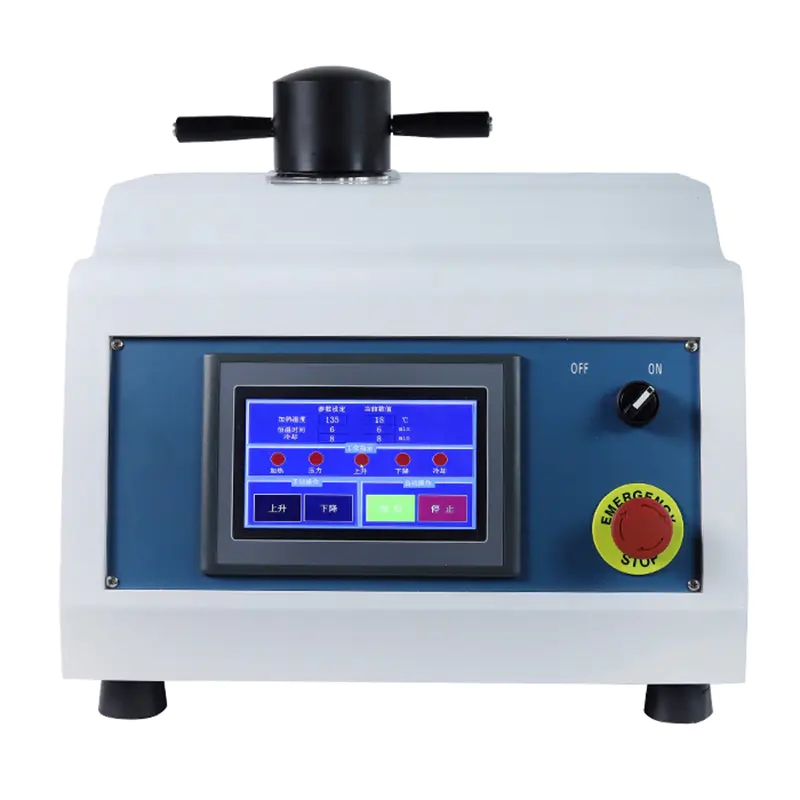

The metallographic sample cutting machine is a cutting device used for cutting and preparing samples during metallographic analysis. It uses a thin rotating abrasive wheel to cut the metallographic samples. It is widely used in metallographic laboratories to cut various metal materials. Due to the presence of a cooling device on this machine, it is used to remove the heat generated during cutting, thus avoiding the change of the metallographic structure of the samples due to heat exposure.

Operation Procedure:

1. Preparations. Connect the water inlet pipe, insert the plug into the power socket, start the motor, and check the rotation direction of the motor shaft. The rotation direction of the shaft should be clockwise.

2. Removal and replacement of grinding wheel. Loosen the screws on the cover, remove the cover. Rotate the screws on the water flow disc and remove the water flow disc. Insert the opening of the wrench into the two flat surfaces of the shaft sleeve, with one end placed at the front end of the base. Use another wrench to remove the clamping nuts one by one and remove the grinding wheel disc. Put the grinding wheel disc back in the opposite way, with two thick paper sheets made into pads placed on both sides of the grinding wheel disc. The newly installed grinding wheel disc should be allowed to rotate for a while to ensure safe operation.

3. Clamping for the test. Use the support plate to hold the saw frame in place to prevent it from falling. Place the specimen in front of the jaws of the saw frame. Turn the handle clockwise to clamp the specimen.

4. Cutting of the sample. With your right hand, lift the handle. With your left hand, press the support plate downward, so that the front end of the support plate passes over the pivot height on the water flow disc. Hold the handle with your right hand to gradually bring the sample closer to the grinding wheel. Adjust the knob and the cooling tube to make the direction and volume of the cooling fluid suitable for the cutting requirements. During the cutting process, make sure the water flow is directed towards the cutting position of the sample and maintain uniform feed. After the cutting is completed, lift the saw frame to a certain height. The support plate will automatically drop and hold the saw frame. At this point, you can remove the sample.

5. Precautions. It is strictly prohibited to use grinding wheels with cracks. Do not operate without cooling or with insufficient cooling. Grinding wheels with linear speed lower than 35m/s are not allowed.

What are the important points to note?

1. After each use, it is necessary to promptly carry out cleaning and maintenance work. Regularly remove the accumulated dirt in the machine body and the cooling water tank to ensure the smooth and clean return of the coolant.

2. It is strictly prohibited to use worn-out or damaged grinding wheels, or grinding wheels with a linear speed lower than 60 meters per second, for cutting operations to ensure safety during the cutting process.

3. The coolant needs to be replaced regularly to prevent it from deteriorating and losing its effectiveness, which would affect the cutting performance.

4. Lubricating oil should be regularly injected into all the sliding surfaces during operation.

5. When replacing the new cutting blade or grinding wheel, do not apply excessive force when locking the nut to prevent the blade or grinding wheel from cracking and causing an accident.

6. If any abnormal noise occurs, stop immediately and conduct an inspection. Before carrying out any maintenance or replacing the parts, you must first cut off the power supply and wait until the grinding wheel stops.

7. If the equipment experiences shaking or any other malfunctions, it should be immediately shut down for repair.

English

English  Español

Español  Deutsch

Deutsch