We are a trusted partner for quality assurance in the safety and performance oriented aerospace sector. Our advanced metallurgy and testing equipment enables you to meet the strict standards of the aerospace industry, ensuring the reliability and longevity of critical components.

High precision: Our high-resolution metallographic microscopy and sophisticated image analysis software allow you to scrutinize the microstructure of aerospace materials and detect small defects that could affect performance.

Comprehensive testing solution: From non-destructive testing (NDT) to fatigue testing, we offer a complete set of solutions to assess the integrity and durability of components under extreme conditions.

Automotive Industry Precision Solutions

In the automotive industry, where performance, reliability, and safety are paramount, we are your trusted partner for material quality assurance. Our advanced metallographic inspection and analysis equipment empowers you to meet the stringent quality standards of the automotive sector, ensuring the superior performance and long service life of critical components from R&D to mass production.

Microscopic Insight for Perfection: Our high-resolution metallographic microscopes and intelligent image analysis software enable you to delve deep into the microstructure of automotive materials (such as steels, aluminum alloys, castings, coatings). Precisely identify grain size, inclusions, phase distribution, heat treatment effects, and the most minute defects that could compromise component strength and durability.

Comprehensive Quality Verification Suite: From material development and incoming inspection to failure analysis, we deliver end-to-end metallographic testing solutions. This encompasses precise hardness testing (Vickers, Rockwell, Brinell), coating thickness and adhesion evaluation, cleanliness analysis, and specialized fatigue and wear testing for critical parts (e.g., engine blocks, crankshafts, gears, fasteners), providing a thorough assessment of their structural integrity and endurance under demanding operating conditions.

Metal Manufacturing Precision Solutions

In the metal manufacturing industry, where quality, process reliability, and cost-efficiency are paramount, we are your steadfast partner for comprehensive material analysis and quality control throughout the entire production chain. Our advanced metallographic inspection and evaluation equipment empowers you to precisely manage the critical microstructural characteristics of metal products—from raw material intake to final goods shipment—ensuring they meet the stringent demands of diverse applications while continuously optimizing manufacturing processes.

Microscopic Insight, Forging the Foundation of Quality: Our high-resolution metallographic microscopes and intelligent analysis systems enable you to delve deep into the microstructure of various metal materials (such as carbon steels, alloy steels, stainless steels, non-ferrous metals, specialty alloys). Accurately assess grain size, phase distribution, non-metallic inclusions, microsegregation, heat treatment microstructure (e.g., case hardening depth, tempering level), and defects arising from casting, forging, or welding, providing the core foundation for material performance and process stability.

End-to-End Quality Assurance Suite: We deliver metallographic testing solutions covering the entire metal manufacturing value chain:

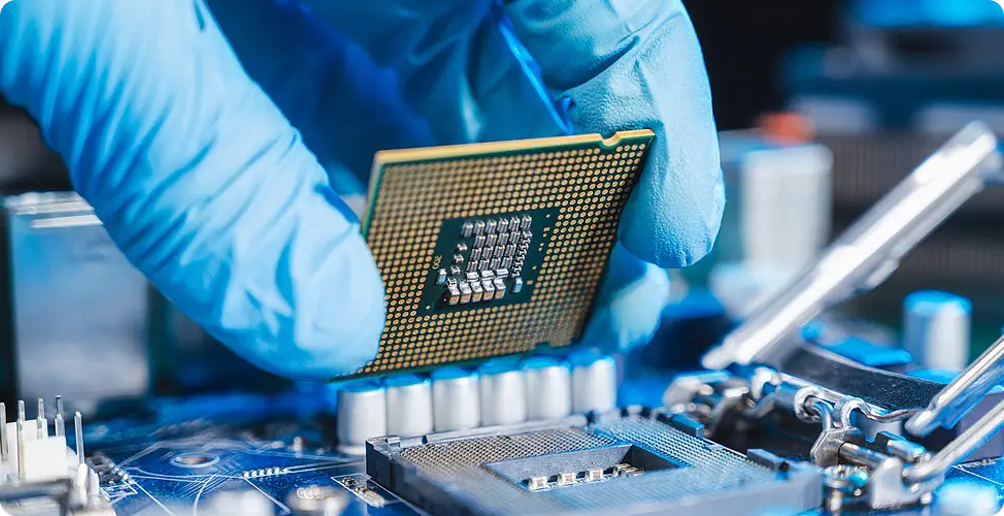

Electronics & Semiconductor Precision Solutions

In the electronics and semiconductor industry, where ultimate performance, miniaturization, and ultra-high reliability are paramount, we are your indispensable partner for material microstructure and failure analysis expertise. Our advanced metallographic solutions operate at the sub-micron to nanoscale. They empower you to explore the intricate microstructures of chips, packages, substrates, and critical materials with precision. We ensure product yield, performance, and long-term reliability from R&D to mass production, accelerating your innovation journey.

Nanoscale Insight, Powering the Future of Microelectronics: We provide industry-leading high-resolution/ultra-high-resolution metallographic microscopes, scanning electron microscopes (SEM), and advanced sample preparation equipment (e.g., precision cutting, grinding/polishing, ion milling CP/FIB).

This enables clear characterization of microstructures in silicon wafers, compound semiconductors (e.g., GaN, SiC), metal interconnect layers, solder joints/bumps, packaging materials (EMC, Underfill), ceramic substrates, and more:

Full Lifecycle Quality & Reliability Assurance: We deliver solutions spanning the entire electronics and semiconductor chain—from design, fabrication, and packaging to testing and failure analysis: