In the meticulous world of materials science, quality control, and failure analysis, the ability to see the internal structure of a material is paramount. The upright metallographic microscope stands as the cornerstone instrument for this vital task. Unlike biological microscopes, these specialized tools are engineered to examine the microstructure of opaque specimens, typically metals, alloys, ceramics, and composites, revealing critical information about grain size, phase distribution, inclusions, and defects. This in-depth guide, drawing upon the expertise of Hangzhou Jingjing Testing Instrument Co., Ltd., will explore the intricacies of upright metallographic microscopes, from their fundamental operation to advanced selection criteria and best practices. We aim to equip professionals and researchers with the knowledge to leverage this powerful tool effectively within their quality management and research systems.

Understanding the Upright Metallographic Microscope

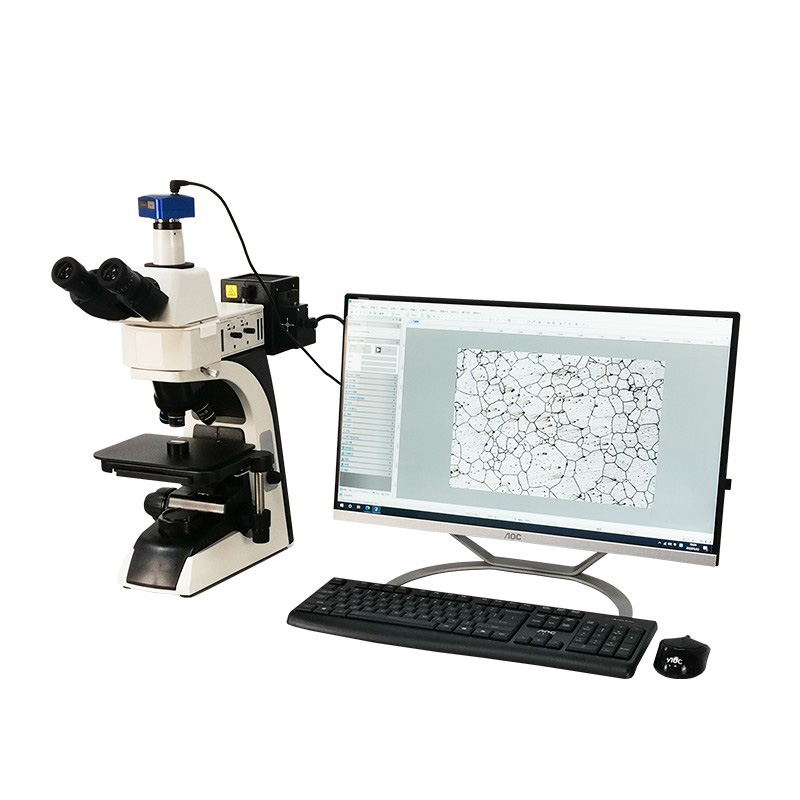

An upright metallographic microscope is characterized by its optical path design where the objective lens is located above the specimen stage. Light is directed down through the objective onto the specimen's prepared surface, and the reflected light travels back up through the same objective to form the image. This design is ideal for observing flat, polished, and often etched samples that are too heavy or large for inverted models.

Core Components and Their Functions

Illumination System

- Light Source: Typically LED or halogen, providing bright, stable Kohler illumination for even sample lighting.

- Aperture and Field Diaphragms: Control contrast and illuminate only the area of interest, reducing stray light.

Optical System

- Objectives: The most critical component. Metallurgical objectives are designed for use without a cover slip and have long working distances.

- Eyepieces and Camera Ports: For visual observation and digital image capture, facilitating documentation and analysis.

Mechanical System

- Robust Stage: A sturdy, often mechanical, stage to hold and precisely position heavy samples.

- Focusing Mechanism: Coarse and fine focus knobs designed to handle the weight of the stage and sample.

Key Applications in Industry and Research

The primary function of a metallographic microscope is to reveal the relationship between a material's microstructure and its macroscopic properties. Here are its core applications:

- Quality Control and Assurance: Verifying material conformity, checking heat treatment results, and detecting processing defects.

- Failure Analysis: Identifying the root cause of component failures by examining fracture surfaces, crack propagation, and microstructural anomalies.

- Research and Development: Studying new alloys, composites, and the effects of various manufacturing processes on microstructure.

- Coating and Plating Inspection: Measuring coating thickness, assessing adhesion, and checking for porosity.

Choosing the Right Upright Metallographic Microscope: A Detailed Guide

Selecting a microscope is not a one-size-fits-all process. The choice significantly impacts the quality of your observations and the efficiency of your workflow. Key considerations include optical performance, illumination, and ergonomics. For instance, when comparing different observation modes, the choice depends heavily on the sample's surface characteristics and the information required.

Brightfield observation is the most common and standard mode for viewing etched microstructures where phases have different light reflectivity. Darkfield observation enhances contrast for features like scratches, pores, and grain boundaries by collecting scattered light, making it superior for detecting surface imperfections and certain non-metallic inclusions. Comparing brightfield vs darkfield metallography reveals that while brightfield is essential for phase identification, darkfield is often the preferred method for inspecting porosity in metal coatings or examining fine surface details. For the most comprehensive analysis, a microscope capable of both modes is highly recommended.

| Feature | Brightfield Illumination | Darkfield Illumination |

|---|---|---|

| Principle | Direct, axial light reflects off the sample into the objective. | Hollow cone of light scatters off surface features into the objective. |

| Best For | Etched microstructures, phase contrast, grain boundaries. | Surface defects, scratches, porosity, grain boundaries (unetched). |

| Image Appearance | Bright background with dark features. | Dark background with bright features. |

Critical Selection Criteria

1. Optical Quality and Magnification

- Objective Lenses: Invest in plan-apochromatic objectives for flat, color-accurate images across the entire field of view.

- Magnification Range: Consider if your work requires high magnification analysis of grain size (1000x and above) or more routine lower magnification inspection.

2. Digital Imaging Capabilities

- A high-quality digital camera and software are no longer optional for modern labs. They are essential for documentation, measurement, and reporting.

- Look for software that offers image stitching, grain size measurement, phase area fraction analysis, and inclusion rating.

3. Illumination Types and Configurations

- LED illumination is now standard due to its long life, cool operation, and stable intensity.

- Ensure the microscope offers the illumination modes you need (brightfield, darkfield, polarized light) either standard or as upgradeable modules.

4. Ergonomics and Upgradeability

- Consider user comfort: binocular/trinocular head angle, placement of controls, and overall stability.

- Choose a system from a reputable supplier like Hangzhou Jingjing Testing Instrument Co., Ltd. that allows for future upgrades (e.g., adding DIC, fluorescence).

Optimizing Performance: Sample Preparation and Microscope Care

The quality of microscopic analysis is directly dependent on sample preparation. Even the best microscope cannot reveal a poorly prepared structure. The process involves sectioning, mounting, grinding, polishing, and often etching. Understanding metallographic sample preparation steps is crucial for any metallographer. For specialized materials like welded joints, a tailored approach is needed. Metallography for welded joint inspection requires careful sectioning to capture the weld metal, heat-affected zone, and base metal, followed by etching techniques that highlight these distinct zones. After preparation, consistent calibration and maintenance are key. Establishing a routine for metallographic microscope calibration ensures measurement accuracy and reliable, repeatable results over time.

Essential Maintenance Practices

- Daily: Clean external surfaces with a soft cloth. Use a blower brush to remove dust from optical surfaces.

- Weekly/Monthly: Carefully clean eyepiece and objective lenses with appropriate lens tissue and solution.

- Annual/As Needed: Schedule professional service to check alignment (Kohler illumination), lamp intensity, and mechanical stage movement. This is where partnering with a provider offering comprehensive metrological management and after-sales support, as practiced by Hangzhou Jingjing Testing Instrument Co., Ltd., becomes invaluable.

Frequently Asked Questions (FAQ)

1. What is the main difference between an upright and an inverted metallographic microscope?

The primary difference lies in the sample placement relative to the objectives. In an upright model, the objective is above the stage; samples are placed top-side up. This is best for standard, manageable-sized samples. In an inverted model, objectives are below the stage; samples are placed face-down. This design is superior for very large, heavy, or irregularly shaped samples as gravity helps with placement and it protects objectives from debris.

2. Why is darkfield illumination sometimes better than brightfield for certain inspections?

Darkfield illumination excels at enhancing contrast for features that scatter light, such as edges, cracks, pores, and fine particles. These features appear bright against a dark background, making them much easier to detect than in brightfield, where they might have low contrast. It is particularly useful for examining unetched samples or for inspecting porosity in metal coatings.

3. How often should I calibrate my metallographic microscope, and what does calibration involve?

A formal calibration should be performed at least annually to ensure measurement integrity. It involves verifying and adjusting the accuracy of the magnification (using a stage micrometer), checking the alignment of the illumination system for proper Kohler illumination, and verifying the linear accuracy of any motorized stage or measuring reticle. Maintaining a routine for metallographic microscope calibration is a cornerstone of quality lab management.

4. What are the most critical factors in preparing a sample for grain size analysis?

For accurate high magnification analysis of grain size, preparation is paramount. The sample must be:

- Properly etched to reveal clear, contiguous grain boundaries without over- or under-etching.

- Absolutely free of scratches, smearing, or deformation from the polishing process that could obscure boundaries.

- Representative of the material's true structure, requiring careful selection of the sectioning plane.

5. Can a basic upright metallographic microscope be upgraded later?

Yes, many modular microscopes from professional manufacturers are designed with upgradeability in mind. Common upgrades include adding darkfield, polarized light, or Differential Interference Contrast (DIC) sliders, installing higher-end plan-apochromatic objectives, integrating advanced digital cameras, or adding motorized stages. When selecting a microscope, it's wise to discuss future needs with your supplier.

The upright metallographic microscope is an indispensable tool for unlocking the secrets held within a material's microstructure. From ensuring product quality to driving material innovation, its role is critical. Success hinges on a triad of factors: selecting the right microscope for your specific application needs (considering modes like brightfield vs darkfield metallography), mastering the art of sample preparation (including specialized techniques like metallography for welded joint inspection), and committing to consistent instrument care. As a comprehensive enterprise specializing in the entire ecosystem of testing instruments, from production and R&D to metrological management, Hangzhou Jingjing Testing Instrument Co., Ltd. understands that this instrument is more than just hardware—it's a partner in achieving precision and reliability. Guided by the principle of "Better price for equal quality; better service for equal price," we are dedicated to supporting your analytical journey with professional instruments, end-to-end technical support, and a commitment to sustainable development in materials science.

References

[1] Vander Voort, G. F. (1999). Metallography: Principles and Practice. ASM International.

[2] ASTM E3-11. (2017). Standard Guide for Preparation of Metallographic Specimens. ASTM International.

[3] Vander Voort, G. F. (2004). Color Metallography. ASM Handbook, Volume 9: Metallography and Microstructures.

English

English  Español

Español  Deutsch

Deutsch