Key Functions and Applications of Metallographic Pre-Processing Equipment in Material Analysis

Metallographic pre-processing equipment plays a crucial role in material analysis by ensuring that samples are properly prepared for microscopic examination. Before the structural and compositional features of a material can be accurately observed, it must undergo a series of pre-processing steps, including cutting, mounting, grinding, and polishing. High-quality equipment for these processes not only improves the precision and efficiency of metallographic analysis but also enhances the reliability of test results.

Key Functions of Metallographic Pre-Processing Equipment

Metallographic pre-processing equipment is designed to prepare metal and alloy specimens for microscopic observation and hardness testing. Each step in the process contributes to revealing the true internal structure of a material without introducing artifacts or deformation.

| Equipment Type |

Main Function |

Typical Application |

| Cutting Machine |

Precisely sections the material sample without altering its structure. |

Used for preparing small, representative pieces from larger metal components. |

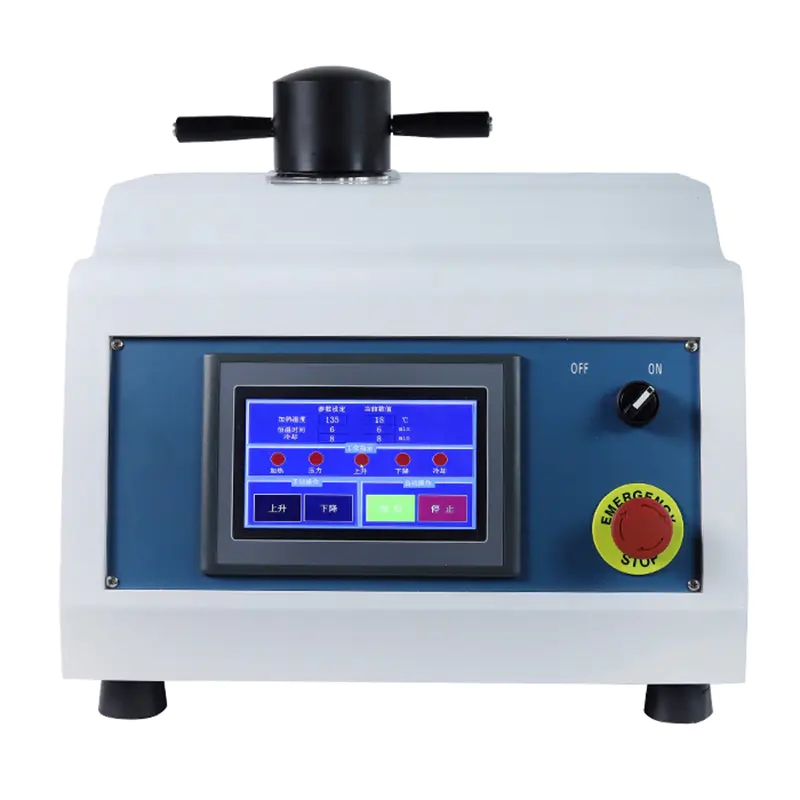

| Mounting Press |

Encapsulates specimens in resin for easier handling and edge protection. |

Ideal for small or irregularly shaped samples requiring stable support during grinding and polishing. |

| Grinding Machine |

Removes surface irregularities and oxidation layers. |

Ensures a flat and smooth surface for subsequent polishing and microscopic analysis. |

| Polishing Machine |

Achieves mirror-like finishes to reveal microstructural details. |

Used prior to etching and microscopic examination. |

| Etching Equipment |

Highlights grain boundaries and microstructural features. |

Used after polishing to expose specific material characteristics. |

Applications in Material Analysis

Metallographic pre-processing equipment is widely applied in laboratories, manufacturing facilities, and research institutions to support quality control and material certification processes. The ability to accurately analyze microstructures enables engineers and researchers to evaluate mechanical performance, detect production flaws, and ensure compliance with industry standards. These tools are indispensable in sectors such as aerospace, automotive, metallurgy, and electronic component manufacturing.

Professional Solutions from Hangzhou Jingjing Testing Instrument Co., Ltd.

Hangzhou Jingjing Testing Instrument Co., Ltd. provides a comprehensive range of metallographic pre-processing solutions that cover cutting, mounting, grinding, polishing, and etching processes. Supported by a professional team of experienced engineers, the company continuously engages in technological innovation and cooperation with renowned domestic and international instrument manufacturers. This ensures stable product performance and high cost-effectiveness for laboratory and industrial users alike.

With an extensive product portfolio and nationwide service network, the company delivers complete testing and measurement solutions across the Pearl River Delta, Yangtze River Delta, Central China, East China, and North China regions. Through continuous commitment to sustainable development and customer-oriented service, Hangzhou Jingjing Testing Instrument Co., Ltd. helps laboratories and manufacturing enterprises achieve reliable, repeatable, and accurate metallographic analysis results.

Metallographic pre-processing equipment forms the foundation of material analysis. From precise cutting to final polishing, each process determines the quality of the final microscopic observation. By selecting high-performance equipment and reliable service providers, laboratories can significantly improve testing efficiency and analytical accuracy. As an experienced manufacturer and service provider, Hangzhou Jingjing Testing Instrument Co., Ltd. continues to support industries in achieving high standards of quality control and material evaluation.

How to Choose the Right Metallographic Pre-Processing Equipment for Different Sample Types

Choosing the right metallographic pre-processing equipment is essential for obtaining accurate and reliable results in material analysis. Since different materials vary in hardness, brittleness, and structural composition, the preparation process must be carefully tailored to the sample type. Selecting suitable cutting, mounting, grinding, and polishing machines ensures that the sample’s microstructure remains intact and free from damage during preparation.

1. Consider the Material Hardness

The hardness of the material determines the cutting speed, abrasive type, and polishing process needed. For hard metals such as tool steel or tungsten alloys, equipment with high torque and diamond-based abrasives is required. Softer metals like aluminum or copper benefit from gentler processing to prevent surface deformation and smearing.

| Material Type |

Recommended Cutting Method |

Grinding/Polishing Abrasive |

| Hard Alloys (e.g., Tungsten, Titanium) |

Precision cutting with diamond blade |

Diamond or alumina suspension |

| Medium Hardness Metals (e.g., Carbon Steel) |

Coolant-assisted abrasive cutting |

Silicon carbide paper followed by diamond paste |

| Soft Metals (e.g., Aluminum, Copper) |

Low-speed cutting with fine-grit wheel |

Alumina or colloidal silica suspension |

2. Evaluate the Sample Size and Shape

Large or irregularly shaped samples may require specialized cutting machines with adjustable clamping systems to ensure stability and precision. Compact or delicate specimens, on the other hand, benefit from small-scale precision equipment that minimizes vibration and cutting stress. When choosing mounting presses, it’s important to match the mold size and material to the specimen geometry for secure handling during subsequent steps.

3. Match Equipment to Testing Requirements

Different analysis objectives call for different levels of surface finish and preparation detail. For routine inspections, semi-automatic grinding and polishing machines provide efficiency and consistency. For high-precision research, fully automatic systems with programmable control settings deliver superior repeatability and surface quality. If etching or coating analysis is part of the workflow, compatible etching systems and fume extraction setups are also recommended.

4. Consider Automation and Efficiency

Modern metallographic pre-processing equipment often integrates automation features such as programmable pressure control, digital monitoring, and sample tracking. These features reduce operator error and ensure uniform preparation, especially in laboratories processing large sample volumes. Automated systems also improve reproducibility, saving time while maintaining consistency across multiple tests.

5. Assess Maintenance and Consumable Compatibility

Equipment durability and ease of maintenance are key factors in long-term performance. Users should choose machines compatible with standard consumables—such as polishing cloths, abrasives, and lubricants—to avoid high replacement costs. Easy-to-clean designs and robust construction also contribute to longer equipment lifespans and more stable results over time.

Selecting the right metallographic pre-processing equipment requires careful consideration of material characteristics, sample geometry, analysis requirements, and operational efficiency. By matching each tool to the sample type and desired outcome, laboratories can achieve high-quality preparation results that lead to accurate and reproducible microstructural analysis.

English

English  Español

Español  Deutsch

Deutsch