What factors should buyers consider when choosing a Metallographic Inlay Machine?

In metallographic laboratories and quality control departments, precision and repeatability are essential for achieving reliable analytical results. One of the key devices supporting these requirements is the metallographic inlay machine, an essential tool used to encapsulate specimens in resin before grinding, polishing, and microscopic observation. Choosing the right machine is not merely a matter of price or brand—it directly influences the consistency of metallographic analysis, operational efficiency, and long-term maintenance costs.

Understanding the Function of a Metallographic Inlay Machine

A metallographic inlay machine (also known as a mounting press) is used to encapsulate small or irregularly shaped specimens in a polymer resin to create a standardized size and shape suitable for subsequent grinding and polishing. This process not only protects the sample edges but also ensures structural integrity during preparation.

There are two common types of inlay processes: hot mounting and cold mounting.

- Hot mounting involves applying both heat and pressure to thermosetting resins. It produces hard, durable specimens with smooth surfaces.

- Cold mounting uses chemical curing resins at room temperature, suitable for heat-sensitive materials.

The performance of a metallographic inlay machine is evaluated based on its temperature uniformity, pressure stability, cooling rate, and resin compatibility. Therefore, buyers should assess how each model aligns with their specific metallographic applications, sample sizes, and throughput requirements.

Company Background and Technical Capabilities

Hangzhou Jingjing Testing Instrument Co., Ltd. is a comprehensive enterprise specializing in the R&D, manufacturing, sales, and service of metallographic microscopes, tensile testing machines, hardness testers, and metallographic sample preparation systems. The company’s team of engineers has participated in multiple technical collaborations with domestic instrument manufacturers, which has contributed to the continuous improvement of metallographic analysis technology in China.

Its research and development infrastructure includes advanced laboratories and partnerships with several universities, supporting innovation in the field of metallographic specimen preparation. The company’s experience and technical resources ensure that its metallographic inlay machines meet diverse industrial needs while maintaining compliance with ASTM E407 standards.

Furthermore, their AI-based image analysis system achieves a defect detection accuracy of 99.5%, enhancing the overall precision of metallographic workflows. These technological advancements demonstrate the company’s commitment to delivering integrated, intelligent solutions for quality control applications.

Factors to Consider When Choosing a Metallographic Inlay Machine

1. Mounting Type and Application Compatibility

The first consideration when selecting a metallographic inlay machine is the type of mounting process required. Hot mounting machines are ideal for applications demanding fast throughput and high durability, while cold mounting systems are preferred for delicate or heat-sensitive materials such as aluminum alloys, composites, and polymers.

Buyers should evaluate their sample materials and temperature tolerance before selecting the machine type. Additionally, laboratories handling various materials may benefit from a dual-function system capable of both hot and cold mounting.

2. Temperature and Pressure Control Precision

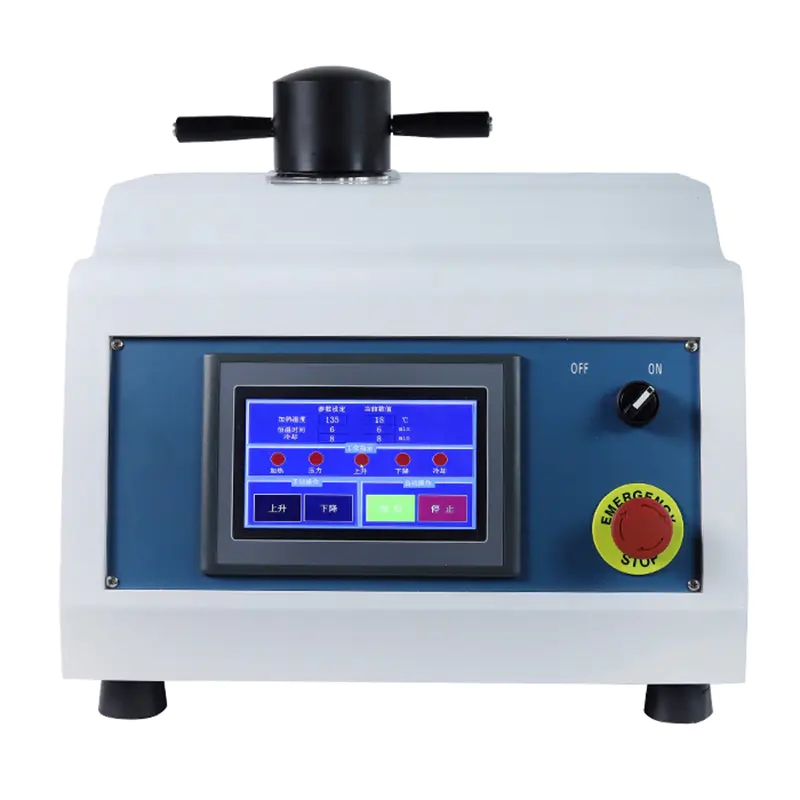

The consistency of mounting quality largely depends on the machine’s temperature and pressure regulation systems. In advanced metallographic inlay machines, digital control panels and programmable settings allow precise adjustments of heating, pressing, and cooling cycles.

Machines equipped with closed-loop temperature control can ensure uniform curing, minimizing voids and incomplete embedding. Similarly, stable pressure regulation prevents resin deformation and ensures strong adhesion between the sample and the resin. Buyers should look for systems offering reproducible results across multiple samples.

3. Cooling System Efficiency

After heating, the cooling stage determines production efficiency and sample stability. Efficient cooling reduces cycle times and prevents internal stress within the mounted specimen.

Modern metallographic inlay machines often use air or water cooling systems. Water cooling generally provides faster thermal dissipation and is suitable for laboratories with high sample throughput. Conversely, air cooling systems are simpler, require less maintenance, and are ideal for smaller laboratories or educational settings.

When choosing between cooling methods, buyers should consider both their operational workload and environmental conditions.

4. Capacity and Productivity

Laboratories vary widely in their sample processing needs. For instance, a research institution might process only a few samples daily, while a metallurgical production facility could prepare dozens.

The specimen chamber capacity—usually ranging from 25 mm to 50 mm in diameter—determines the machine’s output volume. Some models support dual or multi-station operation, allowing simultaneous mounting of multiple specimens. This feature significantly increases productivity and is recommended for laboratories requiring continuous operation.

5. User Interface and Automation Features

Ease of operation is a critical aspect influencing workflow efficiency and error reduction. Many modern metallographic inlay machines feature digital touchscreens with programmable parameters for heating time, pressure, and cooling duration.

Automation enables operators to store customized mounting programs for specific materials, minimizing human error and ensuring repeatability. For instance, an automatic closing and pressure release mechanism improves safety and consistency during operation.

In addition, data logging features can help trace process parameters, which is valuable for quality assurance and compliance audits.

6. Material Compatibility and Resin Type

Different resins exhibit varying levels of hardness, transparency, and shrinkage. Thermosetting resins such as phenolic, epoxy, and acrylic are commonly used. Each has distinct advantages:

- Phenolic resin: economical and suitable for general applications.

- Epoxy resin: excellent adhesion and low shrinkage, ideal for sensitive materials.

- Acrylic resin: transparent and fast-curing, useful for microstructure observation.

A well-designed metallographic inlay machine should support a wide range of resin materials and offer adjustable temperature settings to match their curing characteristics.

7. Durability, Safety, and Maintenance

Given that metallographic inlay machines operate under high temperature and pressure, safety and mechanical robustness are vital. Buyers should prioritize models with high-strength steel chambers, safety interlocks, and overheat protection systems.

Maintenance accessibility is another important factor. Machines with modular designs and easy-to-clean components simplify routine maintenance, extending service life. Availability of spare parts and after-sales technical support also affect long-term operational reliability.

8. Energy Consumption and Environmental Considerations

Energy efficiency has become a growing concern for laboratories aiming to reduce operational costs and environmental impact. Machines with advanced heating systems and optimized insulation reduce energy waste while maintaining stable performance.

Some manufacturers have introduced eco-friendly designs with reduced noise levels and recyclable components, aligning with global sustainability goals. When evaluating a metallographic inlay machine, buyers should consider not only its performance but also its environmental footprint.

9. After-Sales Support and Technical Service

Technical support plays an essential role in ensuring machine longevity and consistent performance. Hangzhou Jingjing Testing Instrument Co., Ltd. provides comprehensive after-sales support, including calibration, maintenance, and user training.

Their team of experienced engineers assists customers in equipment installation, process optimization, and troubleshooting. In addition, they offer customized solutions based on user-specific operating environments. Such services are particularly valuable for enterprises implementing large-scale metallographic analysis systems or seeking ISO certification compliance.

Comparison of Key Selection Factors

| Evaluation Aspect |

Description |

Buyer Consideration |

| Mounting Type |

Hot or cold inlay |

Match with material temperature sensitivity |

| Temperature Control |

Adjustable and uniform heating |

Look for digital programmable control |

| Pressure Regulation |

Constant and stable pressure |

Ensure uniform embedding |

| Cooling Method |

Water or air cooling |

Choose based on throughput and lab setup |

| Automation |

Manual or automatic control |

Improves consistency and safety |

| Specimen Capacity |

Single or multi-station operation |

Depends on sample volume needs |

| Resin Compatibility |

Phenolic, epoxy, acrylic |

Select based on application |

| Maintenance |

Accessibility and part availability |

Reduces downtime and cost |

| Energy Efficiency |

Heating and cooling performance |

Impacts long-term cost and sustainability |

This comparison highlights that no single model suits all users. The optimal metallographic inlay machine depends on individual laboratory requirements, sample characteristics, and desired productivity levels.

Integration with Metallographic Workflows

A metallographic inlay machine is typically the first step in the sample preparation process, followed by grinding, polishing, and etching. Its performance affects all subsequent stages. Poor inlay quality can result in specimen edge rounding, detachment, or microcracks, which compromise microscopic examination.

Therefore, buyers should view the inlay machine as part of a complete workflow, ensuring compatibility with polishing and inspection instruments. Hangzhou Jingjing Testing Instrument Co., Ltd. offers integrated systems that harmonize all these steps, enabling seamless sample preparation and accurate metallographic analysis.

Technological Trends in Metallographic Inlay Equipment

Recent technological advancements have focused on automation, smart controls, and precision enhancement. New models incorporate touchscreen interfaces, real-time monitoring, and automatic pressure release for improved safety and reproducibility.

Furthermore, digital connectivity enables remote operation and process data recording, supporting laboratory digitalization initiatives. As AI and image recognition technologies become more prevalent in metallography, equipment such as the metallographic inlay machine will play an increasingly critical role in achieving reliable, data-driven analysis.

Conclusion

Selecting the right metallographic inlay machine requires a careful assessment of technical parameters, application needs, and service support. Key factors include mounting type, control precision, cooling efficiency, automation features, and long-term reliability.

By choosing an appropriate model, laboratories can ensure consistent specimen preparation and enhance the accuracy of metallographic analysis. With strong R&D capabilities, technical expertise, and professional service infrastructure, Hangzhou Jingjing Testing Instrument Co., Ltd. continues to provide efficient and reliable solutions that meet the evolving demands of material analysis and quality assurance industries.

Ultimately, the decision should be guided by both current operational needs and future scalability—ensuring that every investment in a metallographic inlay machine delivers measurable value and long-term performance stability.

English

English  Español

Español  Deutsch

Deutsch