In the fields of materials science, quality control, and failure analysis, the ability to examine the microstructure of metals and alloys is paramount. While traditional benchtop microscopes have been the laboratory standard, the evolution of technology has given rise to a powerful and flexible alternative: the portable metallographic microscope. This guide delves deep into this essential tool, exploring its applications, key selection criteria, and how it compares to its stationary counterparts, with a focus on empowering professionals to make informed decisions.

What is a Portable Metallographic Microscope?

A portable metallographic microscope is a compact, often handheld or easily transportable instrument designed for on-site microstructural analysis. It enables metallurgists, engineers, and inspectors to perform critical examinations without the need to cut and transport samples back to a central laboratory. This capability is revolutionizing fields where immediate, in-situ analysis is crucial for decision-making.

Core Components and Technology

- Optical System: Utilizes advanced lenses and illumination (often LED) to provide bright, clear images of prepared metal surfaces.

- Digital Imaging: Most modern portable models integrate a digital camera, allowing for image capture, measurement, and live sharing of results.

- Power Supply: Designed for field use with rechargeable battery packs, ensuring hours of operation away from power outlets.

- Portable Design: Lightweight, rugged construction with protective cases for transportation to various environments, from factory floors to remote sites.

Top 5 Applications and Benefits of Portable Microscopy

The primary advantage of portability unlocks a wide range of practical applications that extend far beyond the lab's walls.

1. On-Site Material Verification and Quality Control

- Immediately verify material grade and heat treatment condition on received stock or finished components.

- Perform rapid checks for decarburization, grain size, and inclusion content during production processes.

- Reduce downtime by identifying issues early before they lead to larger-scale production failures.

2. portable microscope for metal failure analysis

- Investigate component failures directly at the site of occurrence, preserving critical context.

- Identify failure origins such as fatigue cracks, brittle fractures, or corrosion damage without moving the often-large failed part.

- Gather immediate evidence to support root cause analysis and prevent future incidents.

3. handheld metallurgical microscope for weld inspection

- Examine weld metal microstructure, heat-affected zone (HAZ) width, and detect imperfections like micro-cracks or lack of fusion.

- Ensure weld procedure qualifications are being followed correctly in construction, pipeline, and shipbuilding projects.

- Provide real-time feedback to welding operators, enhancing process control and quality.

4. In-Service Component Inspection and Maintenance

- Monitor microstructural degradation in critical components like turbine blades, boiler tubes, and pipelines during scheduled maintenance.

- Assess phenomena like creep, spheroidization, or sigma phase embrittlement without removing components from service.

5. field metallography kit for grain size measurement

- Perform ASTM E112 grain size analysis directly in the field for materials like steels and non-ferrous alloys.

- Essential for verifying that materials meet specification requirements for grain size, which directly impacts mechanical properties.

- Advanced kits include software for automatic grain boundary detection and calculation, improving speed and reproducibility.

Portable vs. Benchtop Metallographic Microscopes: A Detailed Comparison

Choosing between a portable and a benchtop microscope depends heavily on your specific needs. The following analysis highlights the key differences.

While benchtop microscopes generally offer higher maximum magnification and superior optical performance for research-grade analysis, portable microscopes provide unparalleled flexibility and speed for on-site applications. Benchtop models require a prepared sample to be brought to the instrument within a controlled lab environment, whereas portable microscopes bring the instrument to the sample, often with minimal preparation. The initial investment for a high-end benchtop system is typically significantly higher than for a portable system, though portable models with advanced digital capabilities can represent a substantial value for their specific use case. Finally, the core advantage of portables is their ability to enable immediate, in-situ decision-making, which is simply not possible with a stationary benchtop unit confined to a laboratory [1].

| Feature | Portable Metallographic Microscope | Benchtop Metallographic Microscope |

|---|---|---|

| Primary Advantage | Mobility & On-site Analysis | Optical Performance & Stability |

| Typical Magnification Range | 50x - 1000x | 50x - 2000x+ |

| Sample Requirement | Often minimal prep; can be used on large, unmovable parts | Requires small, fully prepared sample mounted in lab |

| Environment | Field, factory floor, remote sites | Controlled laboratory |

| Investment Cost | Generally Lower to Mid-Range | Mid-Range to Very High |

| Best For | Routine QC, failure analysis, in-service inspection, education | Advanced R&D, high-precision measurement, publication-grade imaging |

How to Choose the Right Portable Metallographic Microscope

Selecting the ideal instrument involves considering several technical and practical factors.

Key Selection Criteria

- Magnification and Resolution: Match the range to your most common analyses (e.g., 200x-500x for general microstructure, 1000x for fine details).

- Digital Camera Capability: Consider sensor resolution (megapixels), live video frame rate, and compatibility with measurement and reporting software.

- Illumination: Bright, uniform LED lighting is standard. Adjustable intensity and different modes (brightfield, darkfield) add versatility.

- Battery Life and Durability: For true field use, seek long battery life and a rugged, ergonomic design built for industrial environments.

- Software and Connectivity: User-friendly software for capture, annotation, measurement, and generating reports is essential. Wi-Fi/Bluetooth for data transfer is a major plus.

best portable microscope for coating thickness measurement

For applications focused on coating thickness measurement, specific features become critical. Look for a model that offers:

- Calibrated magnification specifically for measurement standards.

- Integrated software with dedicated coating measurement modules that can calculate thickness based on cross-sectional images.

- High depth of field to keep the entire coating layer in focus for accurate edge detection.

- A stable, repeatable positioning system to ensure measurement consistency.

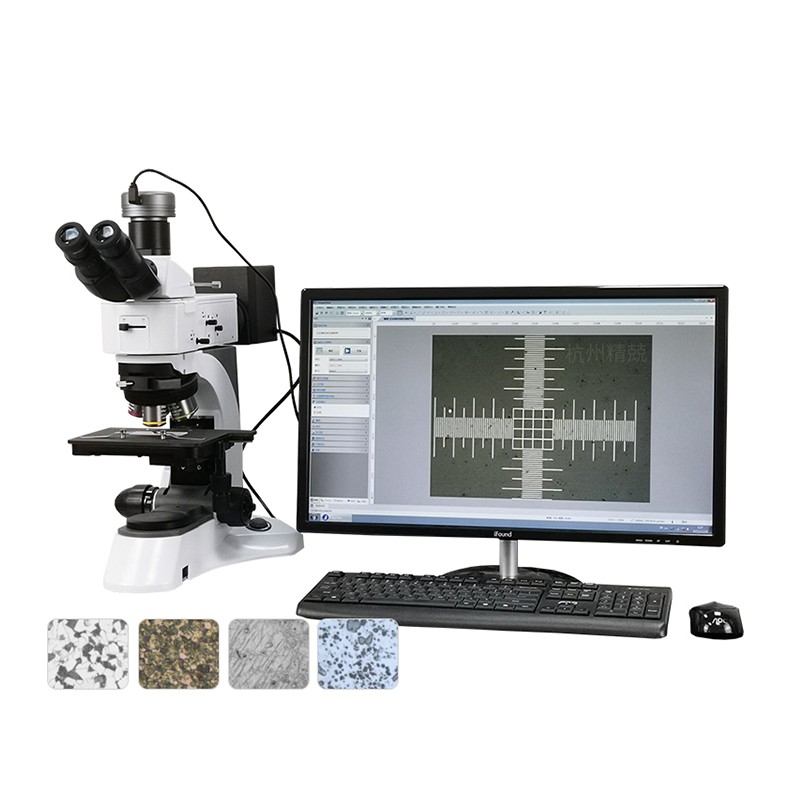

affordable digital metallographic microscope for Educational Use

Institutions and training centers often seek an affordable digital metallographic microscope that doesn't sacrifice core functionality. Key considerations include:

- Sufficient image quality for teaching core concepts of microstructure.

- Robust construction to withstand handling by multiple students.

- Simple, intuitive software that allows students to easily capture and label images for reports.

- The ability to display live images on a monitor or projector for group instruction.

Metallographic Sample Preparation for Portable Microscopy

Even with portable systems, proper sample preparation is the foundation of a meaningful analysis. While extensive lab preparation isn't always possible on-site, understanding the principles is key.

Essential Field Preparation Steps

- Sectioning: Use a portable cutoff saw to obtain a small sample if possible.

- Grinding & Polishing: Compact, hand-held grinding and polishing tools can create an adequately flat and scratch-free surface for preliminary examination.

- Etching: Apply chemical etches carefully using swabs to reveal microstructure. Proper safety equipment (gloves, goggles) is mandatory.

For the highest quality results, especially for quantitative analysis, samples should ideally be prepared using standard laboratory equipment, which provides superior consistency and reveals finer microstructural details [2].

Why Choose Hangzhou Jingjing Testing Instrument Co., Ltd.?

Selecting a partner for your material testing equipment is as important as selecting the equipment itself. Hangzhou Jingjing Testing Instrument Co., Ltd. stands out as a comprehensive solution provider in this specialized field.

- Deep Expertise: Our team comprises highly regarded engineers and service professionals with extensive experience in technical development projects and collaborations across China's instrument manufacturing sector.

- End-to-End Support: We go beyond sales, offering a complete cycle of pre-sales technical consulting, in-sales training, and comprehensive after-sales technical support, ensuring you get the maximum value from your investment.

- Proven Quality & Value: Guided by our principle of "Better price for equal quality; better service for equal price," we deliver high cost-effectiveness without compromising on product reliability or performance.

- Integrated Solutions: With a product portfolio spanning hardness testers, tensile machines, metallographic sample preparation equipment, and microscopes, we can provide cohesive hardware solutions for your entire quality management and certification needs.

- National Reach: Our established distributor network across major industrial regions in China ensures local support and prompt service wherever our customers are located.

We are committed to sustainable development through integrity and strength, continuously enhancing our offerings to partner with our clients in building a successful future.

Frequently Asked Questions (FAQs)

1. How accurate are measurements taken with a portable metallographic microscope?

The accuracy depends on the microscope's optical calibration, camera resolution, and the measurement software used. When properly calibrated, portable microscopes with digital imaging systems can achieve measurement accuracy suitable for most industrial quality control and failure analysis purposes, such as coating thickness or grain size. For the highest precision required in standards-based certification, results should be verified against measurements from a calibrated benchtop system.

2. Can I use a portable microscope for analyzing non-metallic materials?

Yes. While optimized for metals, many portable metallographic microscopes can effectively examine other materials like ceramics, composites, and certain polymers, provided the sample surface is appropriately prepared to be reflective and flat.

3. What is the typical battery life for a portable model?

Battery life varies by model and usage (e.g., brightness of illumination). A typical high-quality portable metallographic microscope with LED illumination can offer between 4 to 10 hours of continuous use on a single charge, which is sufficient for a full day of fieldwork.

4. Is special training required to operate a portable metallographic microscope?

Basic operation for image capture is generally straightforward. However, effective interpretation of microstructures, proper sample preparation (even minimal), and correct use of measurement software require foundational knowledge in metallurgy and microscopy. Most reputable suppliers, including Hangzhou Jingjing Testing Instrument Co., Ltd., provide operational and application training.

5. How do I maintain and calibrate my portable microscope?

Regular maintenance includes keeping lenses clean with appropriate materials, ensuring the battery is charged and stored correctly, and protecting the unit from extreme shock, dust, and moisture. Optical and digital scale calibration should be performed periodically using a certified stage micrometer, following the manufacturer's guidelines to ensure ongoing measurement accuracy.

The portable metallographic microscope is an indispensable tool for modern industry, bridging the gap between the detailed analysis of the laboratory and the immediate needs of the production floor or field site. From enabling rapid portable microscope for metal failure analysis to ensuring weld integrity with a handheld metallurgical microscope for weld inspection, its applications are vast. Whether your priority is finding the best portable microscope for coating thickness measurement, an affordable digital metallographic microscope for training, or a complete field metallography kit for grain size measurement, understanding your requirements is the first step. By combining this knowledge with the expertise and comprehensive support of a trusted partner like Hangzhou Jingjing Testing Instrument Co., Ltd., you can empower your team with the capability to see, measure, and understand materials at the microscopic level, anywhere it's needed.

References

[1] Vander Voort, G. F. (1999). *Metallography: Principles and Practice*. ASM International. This text establishes the fundamental principles of metallographic analysis, highlighting the importance of sample preparation and optical conditions, which form the basis for comparing laboratory and field techniques.

[2] ASTM E3-11(2017). *Standard Guide for Preparation of Metallographic Specimens*. ASTM International. This standard guide outlines the standardized methods for preparing metallographic specimens, providing the benchmark against which any preparation method, including field techniques, is evaluated for suitability.

English

English  Español

Español  Deutsch

Deutsch